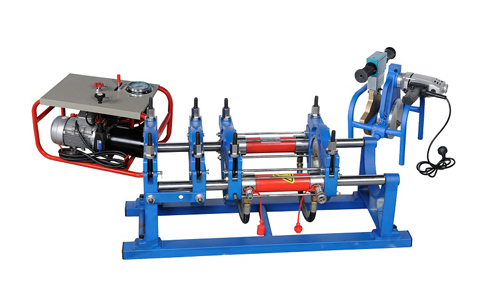

1.It is suitable for pipes or fittings made of PP,PB, PE, PVDF.

2.PH serial welding adopt electric hydraulic docking mode.

3.Consists of basic frame, milling cutter, heating plate, hydraulic unit and steel stand.

4.The main accessories of the welding machines are made by fully automatic aluminum

casting,rustproof,smooth and stronger.

5.Adopt copper motor for stable performance.

6.High hardness milling cutter ,handle the end face easily and tidy. welding the pipe more stronger.

7.Thickened non-stick heating plate with uniform heating,improve work efficiency.

8.The hydraulic unit control the temperature time more easily and accurately . It can save the labor greatly.

·Model:PH4-63/160

·Pipe Size: 63,75,90,110,125,140,160mm

.Docking deviation:≤0.3mm

·Temp.Deviation In Surface: <±3℃

·Total Power: 2.45KW/220V

·Working Temp: 220℃

·Environment Temp: -5℃--+40℃

·Welding Efficiency: <20 Min

·Welding Material:PE PPR PB PVDF

·Model:PH4-63/200

·Pipe Size: 63,75,90,110,125,140,160,180,200mm

.Docking deviation:≤0.3mm

·Temp.Deviation In Surface: <±3℃

·Total Power: 3.05KW/220V

·Working Temp: 220℃

·Environment Temp: -5℃--+40℃

·Welding Efficiency: <20 Min

·Welding Material:PE PPR PB PVDF

·

·Model:PH4-90/250

·Pipe Size: 90, 110, 125,140, 160,180,200,225,250mm

.Docking deviation:≤0.3mm

·Temp.Deviation In Surface: <±3℃

·Total Power: 3.90KW/220V

·Working Temp: 220℃

·Environment Temp: -5℃--+40℃

·Welding Efficiency: <20 Min

·Welding Material:PE PPR PB PVDF